Application Guide: Wiring Commercial Buildings with Fiber Optic Cable

Commercial buildings are increasingly wired with fiber optic cable to future-proof installations and create more reliable, higher-bandwidth and faster speed network and video infrastructures. In larger projects, fiber-based systems also easily exceed the distance limitation of twisted pair-based systems (100m / 330ft.) and provide signal immunity to static, surges, lightning and interference.

Application Drawings:

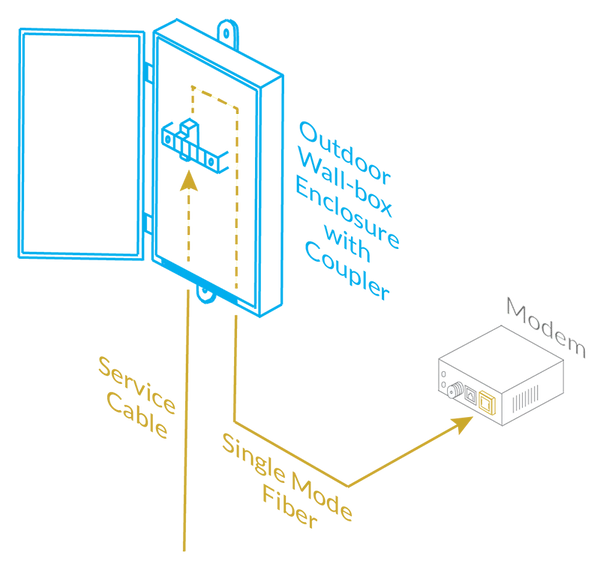

Fiber optic cable is used for everything from demarcation point wiring to network signal distribution to video signal extension. Often, fiber enters the structure to a centralized rack or data room where it is connected to a modem. The modem connects to a network switch which connects each remote point (rooms, floors, distributed network switches, etc.) throughout the facility.

Larger projects often feature a main distribution frame (MDF) that interconnects and manages the telecommunications wiring between itself and remotely located intermediate distribution frames (IDFs). The MDF typically connects external public lines coming into the building with the internal private lines that feed back from the IDFs.

In practice, the MDF is typically centrally located near the demarcation point, whereas the IDFs are located on each floor, wing or unit within the building.

Fiber optic cabling and fiber-ready enclosures, including rack trays and wall-boxes, are often used for MDF and IDF wiring because they support long cable distances and very fast network speeds. Fiber-based systems easily exceed the distance limitation of twisted pair-based systems (100m / 330ft.), and they easily support network speeds exceeding 10Gbps. It’s also common to see multi-strand fiber optic cabling, such as 6 strand and 12 strand, connecting the MDF to the IDFs to accommodate signal distribution to individual rooms and/or devices.

Fiber optic cable is increasingly used to extend video signals such as HDMI, DVI and DisplayPort. Fiber supports the bandwidth required for native 4K HDR (up to 18G) and 8K (up to 48G), and it future-proofs for planned standards such as 12K and 16K.

Video over fiber extenders typically leverage the same standard fiber optic cable and connectors commonly used in data applications, such as duplex multimode OM3 with LC connectors and single mode OS2 with LC connectors.

OOne of the most common applications for fiber optic cabling in any structure is demarcation wiring, including connecting the fiber service feed to the building’s network distribution point. Integrators are commonly faced with:

- Existing installations where the service feed must be moved or extended

- New construction where the service feed isn’t yet installed and a demarcation point must be prepared by the integrator

Both applications typically require an outdoor-rated enclosure with integrated coupler and single mode fiber optic cable terminated with a single mode fiber connector.

Notes When Wiring a Demarcation Point:

Demarcation wiring almost always requires single mode (OS2) fiber optic cable. Never pull multimode fiber to the demarcation point unless specifically required by the internet service provider. All cable before the modem should be single mode fiber.

SC-style connectors are commonly used in demarcation wiring and are available in two formats: APC (angled polish) and UPC (ultra or flat polish). APC connectors are typically green and UPC connectors are typically blue. Always terminate single mode connectors onto single mode fiber and try to match the connector type to the service provider’s connector type. When in doubt, terminate APC (green) connectors.

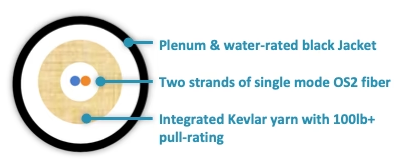

Fiber optic cable is available in a variety of formats. Outdoor rated (weather-proof) cable is used if conduit is in place. Direct burial (weather-proof and armored) cable is used if the cable will be buried directly in the soil.

Commonly Used Prewire Fiber:

Single Mode OS2 #S2I-2M-P-BK-1000 is commonly used to prewire structures. It future-proofs installations for less cost than shielded twisted pair and terminates using standard tools and connectors. It’s small, strong, plenum-rated, outdoor-rated, black jacketed and universally compatible with single mode devices thanks to Corning SMF-28 Ultra® OS2 fiber.

Commonly Integrated Products:

Rack trays provide a secure connection point to connect fiber optic cables and manage service loops. They fit standard 19” and 23” racks. Rack trays require an insert panel for connecting cables.

Insert panels mount inside metal wall-boxes and rack trays. They

feature a variety of pre-mounted fiber optic coupler styles and quickly connect two fiber topic cables.

Indoor/outdoor wall-boxes are ideal for both indoor and outdoor applications. They provide a secure connection point to connect fiber optic cables and manage service loops.

Couplers mount inside indoor/outdoor wall-boxes and physically connect two cables.

Fiber optic keystone wallplate inserts provide a secure and aesthetic cable termination point and/or connection point between the main cable run and a shorter patch cord.

Extenders transmit audio, video and control signals over fiber optic cabling.

Premade fiber optic cables arrive pre-terminated with connectors and are available in stock and custom configurations.

Bulk fiber cable requires termination in the field and is available in stock and custom configurations. Both riser and plenum formats are commonly used to connect networking equipment.

Fiber optic connectors terminate on bulk fiber cable.